Electrical hazards: Keeping employees safe

Electrical hazards, present in a host of industries, claim many lives each year – they’re worth guarding against.

Electricity risks are omnipresent in all kinds of workplaces.

Electrical hazards are one of the most universally relevant dangers to warn employees about because they are so ubiquitous. It’s hard to think of an industry without electrical equipment, and whether or not power generation is a company’s prime business, it pays for leaders to assess potential dangers. The Occupational Safety and Health Administration (OSHA) offers guidance on keeping the workforce safe from exposure to dangerous current, and it will likely take a mixture of good risk management, appropriate use of personal protective equipment (PPE) and relevant training to safeguard employees.

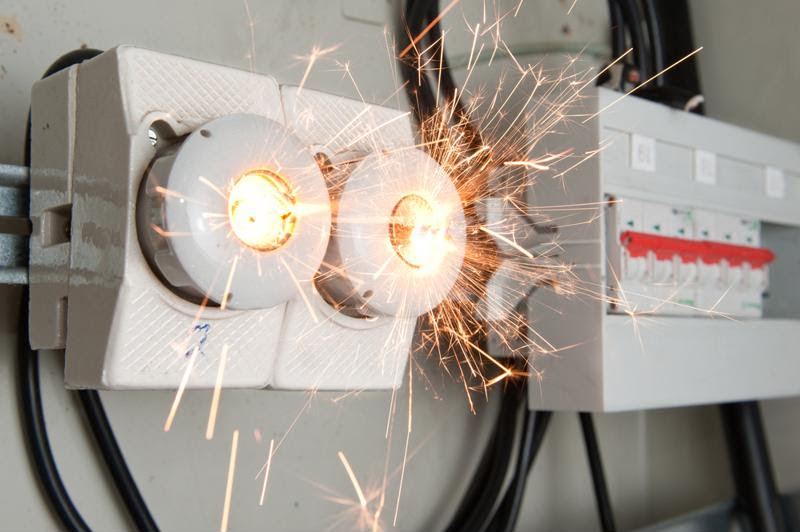

The first step in recognizing and guarding against electrical hazards is to realize that these dangers come in all shapes and sizes. Improperly guarded power sources can cause fires or explosions, and exposure to currents has the potential to do great harm to an employee. Generators, wires and electrical machinery all hold their own dangers – and electrical accidents are all too common.

Workplace accidents are numerous

How dangerous is exposure to electrical current? In construction environments, OSHA considers electrocution one of its “fatal four” accident types, responsible for 81 construction worker deaths in 2015, the latest year for which stats are available – 8.6 percent of the industry total. In fact, among construction laborers, more electricians were killed on the job in 2015 than in any year since 2009, according to data from the Bureau of Labor Statistics.

In more general industry terms, electrical exposure took 134 employees’ lives in 2015 – and that number actually represents a decline from 2014’s 154, as well as 2011’s very high 174. The fact that such accidents do occur on a regular basis – averaging more than one per every three days – should galvanize leaders into acquiring what they need to stop the incidents, whether their efforts take the form of equipment guarding, better training or PPE – or, ideally, all three.

The multiple kinds of protection complement one another. Wearing the right PPE is no substitute for never being around a threat to begin with, and both avoiding danger areas and correctly using gear are skills that can and should be tuned up in training.

Workplaces of all kinds have electricity risks.

Workplaces of all kinds have electricity risks.Major threats and mitigation methods

OSHA lists three major risks that lead to the lion’s share of workplace accidents concerning electricity. Equipment that is naturally unsafe or installed incorrectly is one of these dangers. A risky environment, one in which workers are in jeopardy while simply doing their jobs, is another. The third is using bad work practices on the job. Whether employees never knew the right approach to take or they simply decide to cut corners, doing the wrong thing can land a person and his or her co-workers in immense danger.

As for the best ways to keep employees away from danger, the agency suggests insulating currents, guarding assets, grounding wires, using protective devices and adopting better work practices. It’s worth breaking down these methods and describing what each entails:

- Insulation is any coating applied to a live wire to ensure it doesn’t cause harm. There are several caveats associated with the use of insulation, including the fact that higher-voltage currents take more powerful insulators, and environmental risks such as added moisture or corrosion can make the threat greater. Furthermore, though insulated wires are often color-coded, it’s not worth assuming a wire is safe just based on its color – individuals should treat electric sources as if they’re live.

- Guarding is the process of closing off electrical assets to ensure nobody touches anything dangerous. OSHA notes that for guarding to be considered effective, companies should set up permanent obstructions around equipment operating at greater than 50 volts. Surrounding electrical spaces with warning signs is another essential part of blocking off hazards.

- Grounding is described as an additional method of protecting against electrical hazards, on top of more direct applications such as guarding. It means running a path between an electrical asset and the earth, reducing the chance that it will deliver a deadly shock – OSHA was sure to note the method is not guaranteed to save lives and shouldn’t be the only method a company uses. It’s an essential addition in case of problems.

- Protective devices such as fuses, circuit breakers and interrupters are in common use wherever there’s electricity. Employing them in workplaces is a vital part of creating a secure environment.

- Good practices entail essential safety operations such as powering assets down and wearing PPE. Workers need to keep the correct behaviors in mind and not forget to apply them, even once they’ve become second nature.

Training courses available

Keeping employees up to date on all the potential threats they face from electricity sources is vitally important. This is where training courses come in, often specialized by industry or risk type to ensure workers get a relevant grounding in the practices that could save their lives.

From manufacturing plants to construction sites to laboratories and beyond, MasteryTCN offers courses that encompass multiple facets of electricity safety training.

Source

Great post! Employee safety is clear explained in detail. Keep up the good work.